IoT Applications in Manufacturing Industry

IoT connects consumers, manufacturers and products. This leads to a new era with a more connected environment that enfants collectively. The internet of things is a global technology that is transforming the industry and manufacturing sector. Let us see some of the applications of IoT in manufacturing industry.

Benefits of IoT in manufacturing

- Iot recognize manufacturing delays and helps to identify the underlying causes

- Production units benefit majorly with automation of various processes in the manufacturing industry. This allows the maximum utilization of raw material and manufacturing components.

- IoT leads to better allocation of resources. It allows users to shift their focus on clients and profits rather than worrying about tedious and time consuming tasks.

IoT Applications in Manufacturing Industry

Below are a few of the useful application of IoT in the manufacturing sector:

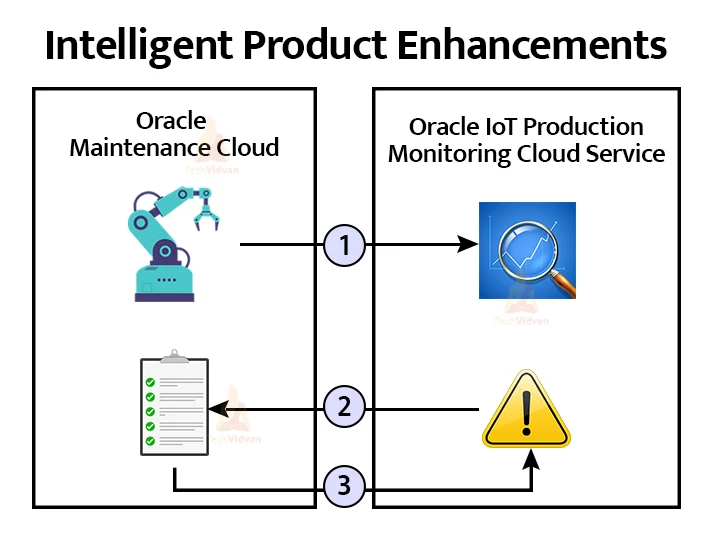

1. Intelligent product enhancements

Similar to the other applications of IoT, IoT in manufacturing also enhances production quality. Previously, the creation of products would require a heavy market research and customer suggestions, with IoT, owners have access to large amounts of data and information. IoT acts as a reliable source of information about any product and hence ensures better profits.

2. Dynamic response to market demands

Supplying to market demands depends on a number of factors such as taste and preferences, income of the population, consumer expectations, country capital and so on. Keeping up with demands requires constant research and present supply could cause heavy losses to business and future decisions.

IoT stores and retrieves information continuously and does not require much human intervention. It controls supply chains because the information IoT gathers is accurate to a large extent

3. Improved facility service

IoT improves the conditions of workplaces and offers safety and security to any typical facility. Safety managers communicate through applications and access real-time information regarding threats and safety events.

This allows organizations to monitor events, enhance communication and increase production.

4. Product safety

Despite a complicated set of operations ensuring customer safety, hazards and dangers still find their way into the market. Unknown reasons may cause serious incidents.

IoT deploys sensibility, control and management techniques to track such incidents and raise alerts in case of potential threats.

5. Lower costs, optimized resource use and waste reduction

IoT replaces manual labour in various domains. It reduces the dependency on humans to perform background checks for products. Maintenance checks and tests usually require manual labour costs and are time consuming. With IoT, one can monitor the status of their organization remotely, through sensors and security webcams.

IoT offers ways to manage and optimize the usage of resources such as humans and minerals. It offers cost effective and feasible methods to complicated problems.

6. Quality control

IoT proposes real-time monitoring of appliances and products in the industry. Manufacturers can predict the breakdown of certain machinery parts and offer solutions instead of waiting for the machine to collapse. IoT benefits systems by monitoring the status of engines, machinery and their mechanism. The automation of certain processes reduces the dependency on manual labour.

7. Predictive maintenance

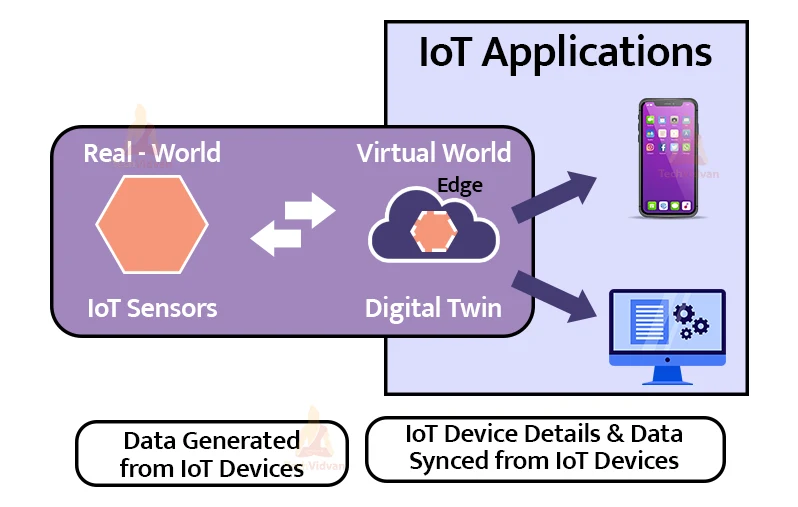

Traditionally, manufacturers use a time based approach to carry out maintenance checks on machinery and engines. However, with IoT in the picture, routine checks are automated. Meaning that the machines carry out their own maintenance without outside support and inform the users about threats via mobile applications.

Iot sensors monitor the operations and perform data analysis on the real time data in clouds.

IoT has led to the automation of various processes. Predictive maintenance is one such automation. It is where the device schedules a routine self maintenance check to keep a track of its functionality. It reports bugs and damages to its authorities who then take actions to fix the ongoing issues. As a result of which owners are not required to manually perform a maintenance check as the machine itself deploys a routine system check in intervals of time.

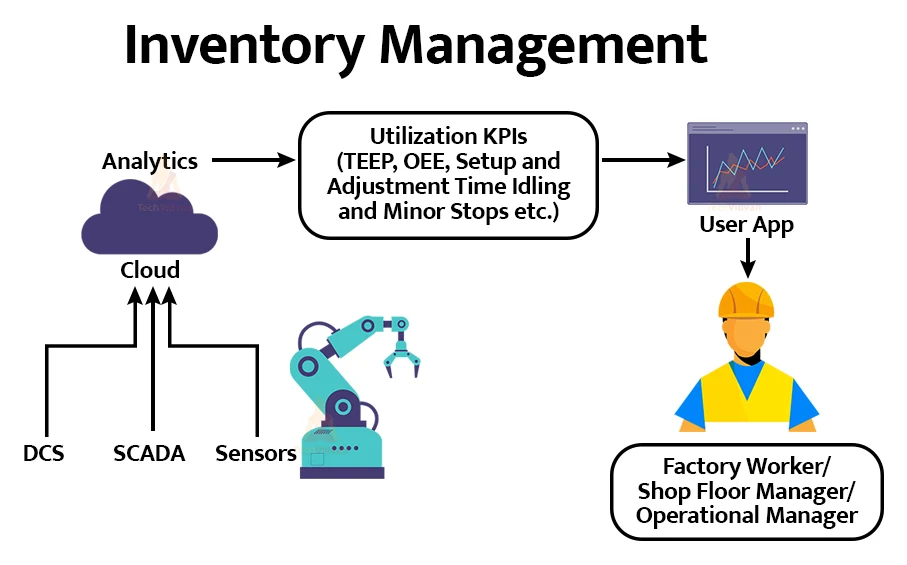

8. Inventory management

RFID and IoT can represent inventory management as a seamless and efficient process. Each inventory comes with an RFID tag and each tag generates its own Unique identification (UID).

The data that RFID tags collect plays a vital role in running most organisations these days. The systems monitor the output of RFID tags and send notifications to users in case of missing inventory.

9. Smart packaging

Smart packaging is an application of the internet of things that uses forms of technology to package products and does more than storing the products. It allows users to interact with the package and resolve their queries regarding the bread, product or delivery.

Iot and packaging work together include sensors, QR code and other options. The main goal is to interact with the consumer and collect necessary data.

10. Smart metering

This allows the consumption of resources in a more effective manner and reduces the wastage of these precious resources. Smart meters track the consumption of water, fuels and electricity. They measure the usage of these resources and deploy methods to consume these resources more efficiently.

11. Supply chain management

IoT devices trace and monitor the real-time data incoming from supply chains. Authorities can monitor and control machinery, equipment, and delivery systems from remote locations. Some IoT systems also offer ERP softwares that reduces the need for manually documenting the processes.

12. Workshop monitoring

Machine workshops are stores where the manufacturing of tools and substances is done. These workshops consume high energy with less efficiency. There exists a complicated energy flow in the manufacturing of these tools and leads to heavy energy consumption.

IoT designs an effective monitoring system to gather and trace the energy consumption by these workshops to improve the conditions. IoT manages the manufacturing process leading to reduction in costs and lesser consumption of energy.

13. Production flow monitoring

One of the important processes in manufacturing is production flow. Manually, it gets difficult to manage and track the production flow. IoT uses sensors that provide the owners with real-time data to monitor the prediction. These sensors give details about the parts of machines and generate service calls when they notice a breakdown or damaged parts.

14. Digital twins

Digital twins is the method of creating exact copies or replicas of actual, hardware devices by using cloud. IoT scientists and IT officials create these models for testing and deploying purposes before they publish the real life model. This technology is now being used in large buildings, construction sites and also in cities.

Summary

So in this article, we have discussed the leading application of the internet of things in the manufacturing sector.